Coherix Highlighted in Manufacturing in Focus Magazine

3D Machine Vision Experts

Coherix, Inc.

Written by Nate Hendley

This article appears in the January 2023 edition of Manufacturing In Focus Magazine

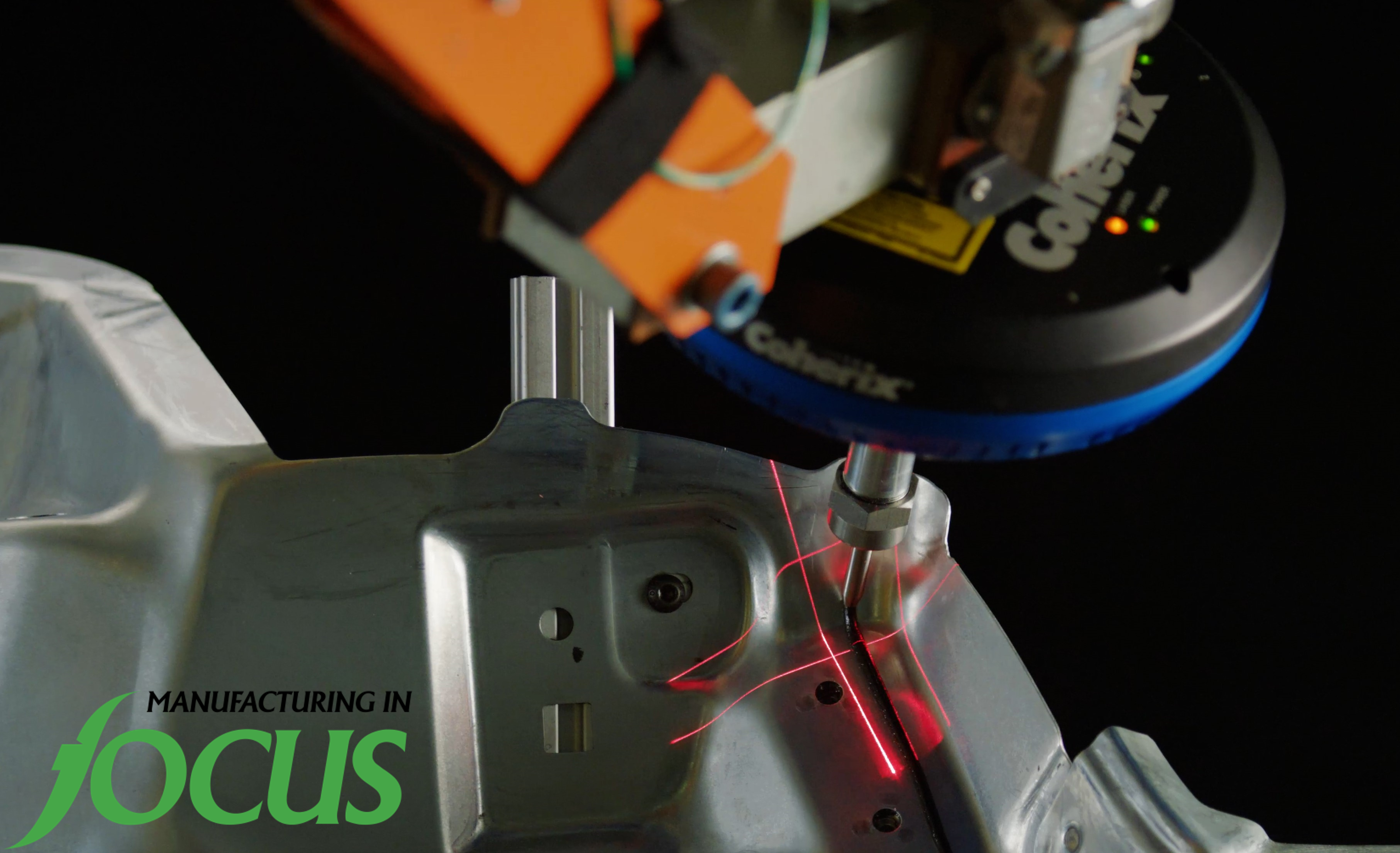

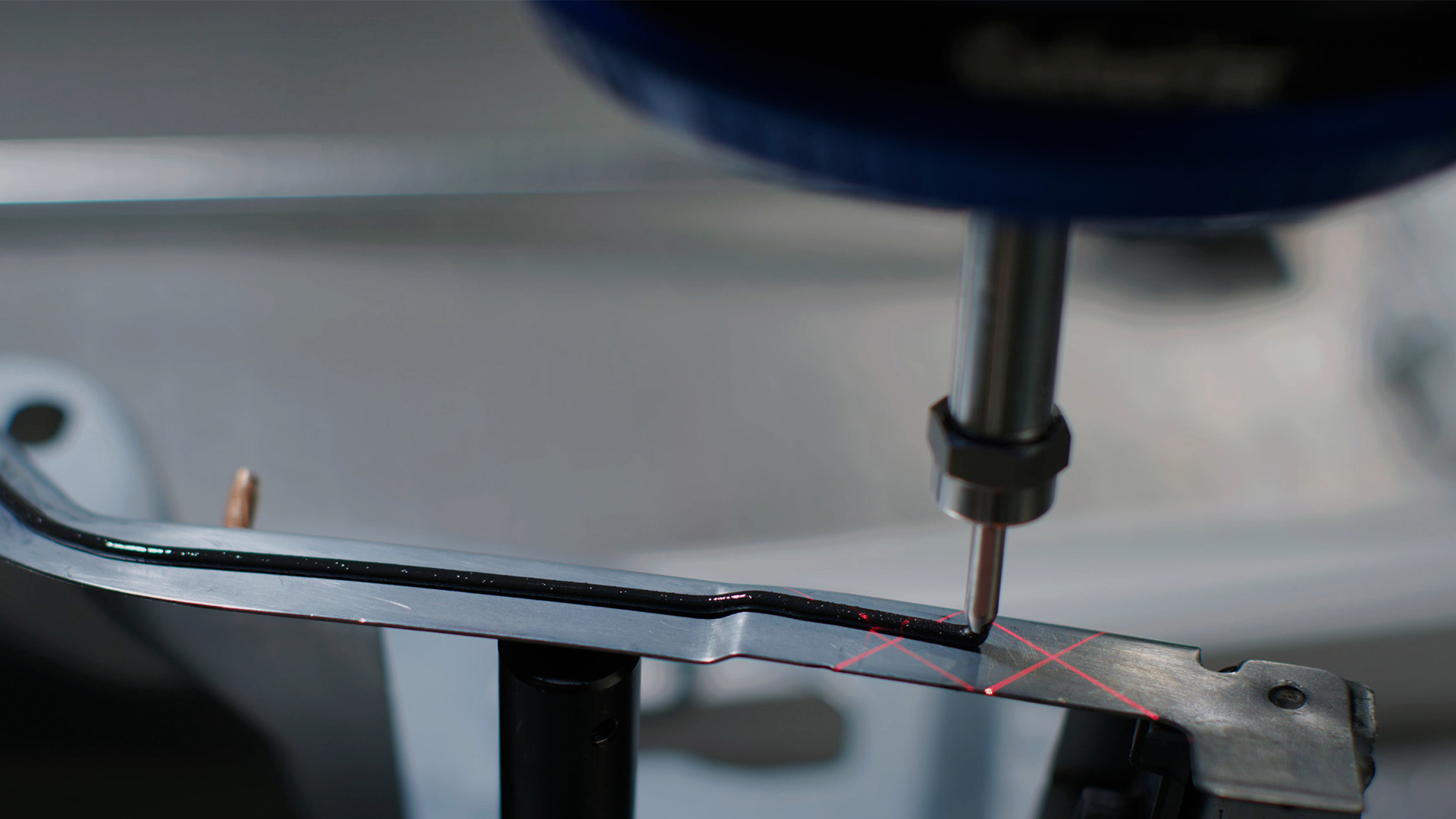

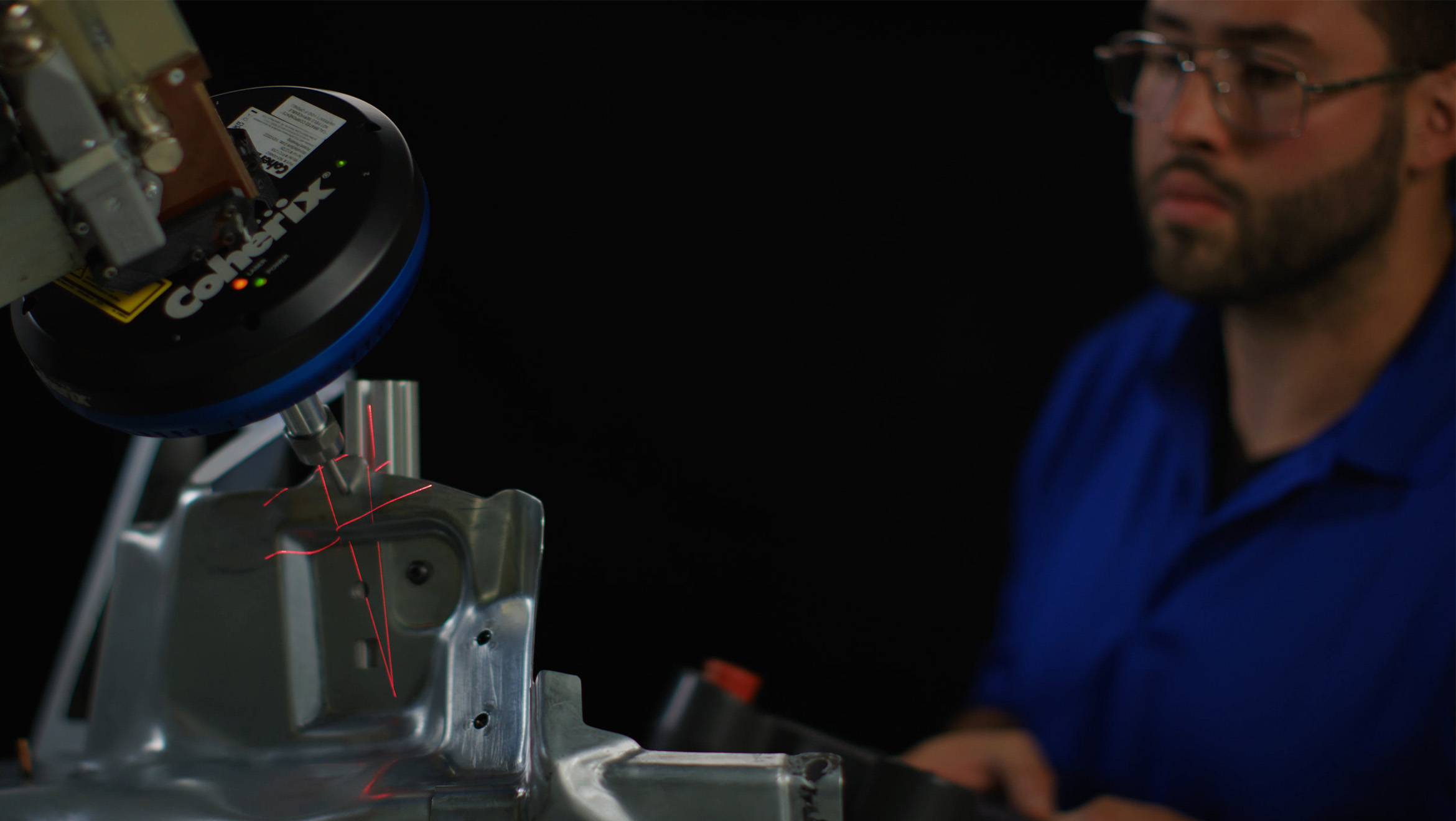

Coherix, Inc., of Ann Arbor, Michigan aims to dominate the precision industrial sealant and adhesive dispensing market through its pioneering products and cutting-edge technology. The company designs and builds three-dimensional (3D) machine vision systems and software for monitoring and inspection.

Its systems can measure the height, width, volume, and location of sealant / adhesive dispensing in manufacturing plants. The in-line data gathered by sensors is analyzed by its proprietary software while its Adaptive Process Control (APC) system adjusts automatically to maintain control in changing conditions.

The company’s systems “have perfected the measurement of process performance. We compare these measurements to pass / fail specifications—essentially sorting bad parts from good parts; however, inspection is ‘non-value added.’ Toyota and other customers have been pressuring Coherix to develop adaptive process control capabilities. We have, and APC is our primary deliverable today,” states Coherix Founder and Chief Executive Officer Dwight Carlson.

APC is an essential element of the ‘factory of the future’ concept which Carlson strongly endorses. Also known as Industry 4.0, the term refers to connected and highly-automated factories in which sensors and monitors glean and transmit production and quality data.

Such facilities “require manufacturing systems that can see in 3D in real time. They must see well enough and think fast enough to operate autonomously… adaptive process control is key, and absolutely necessary for autonomous operation,” he says.

APC allows Coherix to “control the process,” and ensure consistent quality, providing extra value for end customers, adds President Jürgen Dennig.

Coherix products are equipped with a variety of APC-enabled solutions to optimize dispensing. Coherix 3D, one of the company’s leading machine vision systems, features AutoRepair, in which bubbles and gaps in the dispensed adhesive are repaired automatically without human intervention; LocationMaster, which locates parts and transmit information to the robot to modify the dispensing path; and Z-Tracking, which “dynamically adapts to each part’s individual variations to maintain acceptable tip to part distance, preventing broken nozzles and scrapped parts,” says the Coherix website.

Coherix 3D also uses RobotAssist to help programmers maintain the proper tool angle and nozzle distance relative to the surface of the part and NozzleCheck to prevent material build-up at the dispensing nozzle.

Coherix™ Inline Glass Primer Inspection, used for comprehensive in-line inspection and complete part traceability during black and clear primer dispensing, uses LocationMaster, as does Coherix 3D™ Inline Swirl Bead Inspection, which inspects swirl bead dispensing operations.

Coherix espouses total dispensing systems engineering. “People are selling robots; others are selling dispensing equipment; others are selling fixtures for parts, but nobody is taking care of the process in total, and that’s what we do: total dispensing systems engineering. We have the best guys you can get. It’s not about a product; it’s about a process,” states Dennig.

This process analyzes dispensing system performance and warns clients before the dispensing process goes haywire, he adds.

At present, most of Coherix’s efforts are focused on a specific market. “Our primary industry today is automotive, especially Tier One auto suppliers,” Carlson says.

As well as Toyota, Coherix continues to work with VW, Honda, Nissan and Ford, and has a presence in “all of the plants,” of a leading electric vehicle (EV) manufacturer. “We’re kind of their go-to guys on dispensing,” he says. “EVs and battery makers are becoming a significant part of our business. Both accelerate the need for lightweighting, which drives the use of adhesives.”

Lightweighting is all about reducing the weight of planes and cars, to enhance fuel efficiency and drive costs down without sacrificing performance. In a lightweighting process, parts and panels can be manufactured from materials such as carbon-fiber composites to be both light and strong. Parts are not welded together but attached using sealant or adhesive, which is where Coherix comes in.

The company also does some work with vision system integrators and manufacturers that make adhesive dispensing equipment. While it has no intention of moving away from its existing markets, it is eager to branch out into new sectors. To achieve this, it will be releasing the Coherix 3D Mini this year. Designed to be used with mini dispensing machines, this new product differs in size from its conventional counterparts.

“In car manufacturing, usually dispensing systems are sitting on six-axis robots. In mini dispensing, usually they are three-axis—x, y, z systems,” Dennig explains. The 3D Mini will broaden the company’s market reach, he adds.

“Mini dispensing is more for the electronic consumer and medical device industries,” than automotive, he says. “I can tell you the mini-dispensing market is 2.5 times bigger than the dispensing market in automotive, so [the Coherix 3D Mini] is giving us huge opportunities.”

Huge opportunities could in fact be the byword at Coherix, which now has a foothold in multiple regions. Coherix Europe is based in Sinsheim, Germany, while Coherix Asia Pacific is based in Singapore, and Coherix China is in Shanghai. Since we last spoke in 2021, the company has also launched Coherix Japan and Coherix Mexico. The Ann Arbor office oversees both North and South America.

Personnel numbers have also expanded, from roughly seventy people at the time of the previous profile to over eighty today. The company’s success is even more remarkable, given that it is located far from the technology hub of Southern California.

Developing a Silicon Valley-style “high-tech culture in the Midwest,” was difficult, Carlson concedes. While Ann Arbor boasts the highly-regarded University of Michigan and companies that do federal government research, the Midwest is better known for old-school manufacturing and contentious labor / management relations than visionary technology firms. Yet, Carlson has succeeded in establishing a company imbued with a spirit of collaboration and innovation.

Success, however, might beget another problem. Traditionally, as companies get big, they tend to become more conservative and cautious but Carlson does not anticipate any difficulties staying innovative as the firm grows.

In addition to recruiting what he calls “hot-shot engineers,” he has retained certain workplace principles derived from his experience with Hewlett-Packard. In the 1970s, Carlson licensed HP to sell products developed by a previous company he ran.

As part of these principles, stock options are offered to all staff, and the company does not have a rigid hierarchy. “We are a team. Everyone is a team member. We have leaders, managers, coaches, but no bosses! We share the rewards of success with our team members. Everyone is a stockholder,” he notes. It also helps that Coherix is forward-thinking with an eye on emerging technologies and manufacturing trends.

For all this, some situations remain out of its control. The long-term effects of COVID, for example, are still being felt. “We did a great job preventing COVID from infecting our team. However, COVID has negatively impacted our customer base which, in turn, impacted us. We have been very fortunate to be able to continue to grow our precision dispensing business,” Carlson says.

The pandemic interfered with the production of semiconductor chips, which had a ripple effect throughout the world. The semiconductor slowdown caused supply delays and led some original equipment manufacturers to reduce production. Authorities in Shanghai—headquarters for the company’s China operations—locked that city down for months to prevent the virus from spreading. This strict measure made it difficult to do business.

While there was not much Coherix could do about the Shanghai situation, the firm successfully navigated the semiconductor storm.

“We’ve been able to make our deliveries, by the grace of God. We’ve been through semiconductor shortages more than once. We know how to find one thousand parts here, one thousand parts there, whereas the auto guys have to find millions,” says Carlson.

COVID aside, “recruiting global team members that meet Coherix’s high performance standards,” is also a challenge, he says.

While qualifications are important, Coherix wants new hires with the right mindset. “We hire attitudes! We can teach our team members everything else,” he states.

Coherix representatives offer a dynamic forecast, predicated on cutting-edge products and technology and a stellar staff. The goal is to be taking in over $100 million in annual revenue and be listed on the NASDAQ, one of the world’s largest stock exchanges, within five years.

More of Carlson’s market plan might be revealed during this period as well. Having set his sights on one market vertical, he is already contemplating further moves.

“Right now, Jürgen is leading the first business unit—precision dispensing—and I am starting to turn my attention to selecting the second,” he says. “In 2024, I would like to identify our second application, our second market vertical, then you go on to your third and fourth. That’s the strategy.”

View in Manufacturing in Focus Magazine