Coherix 3D Inline Swirl Bead Inspection

Measuring Adhesive Swirl Beads.

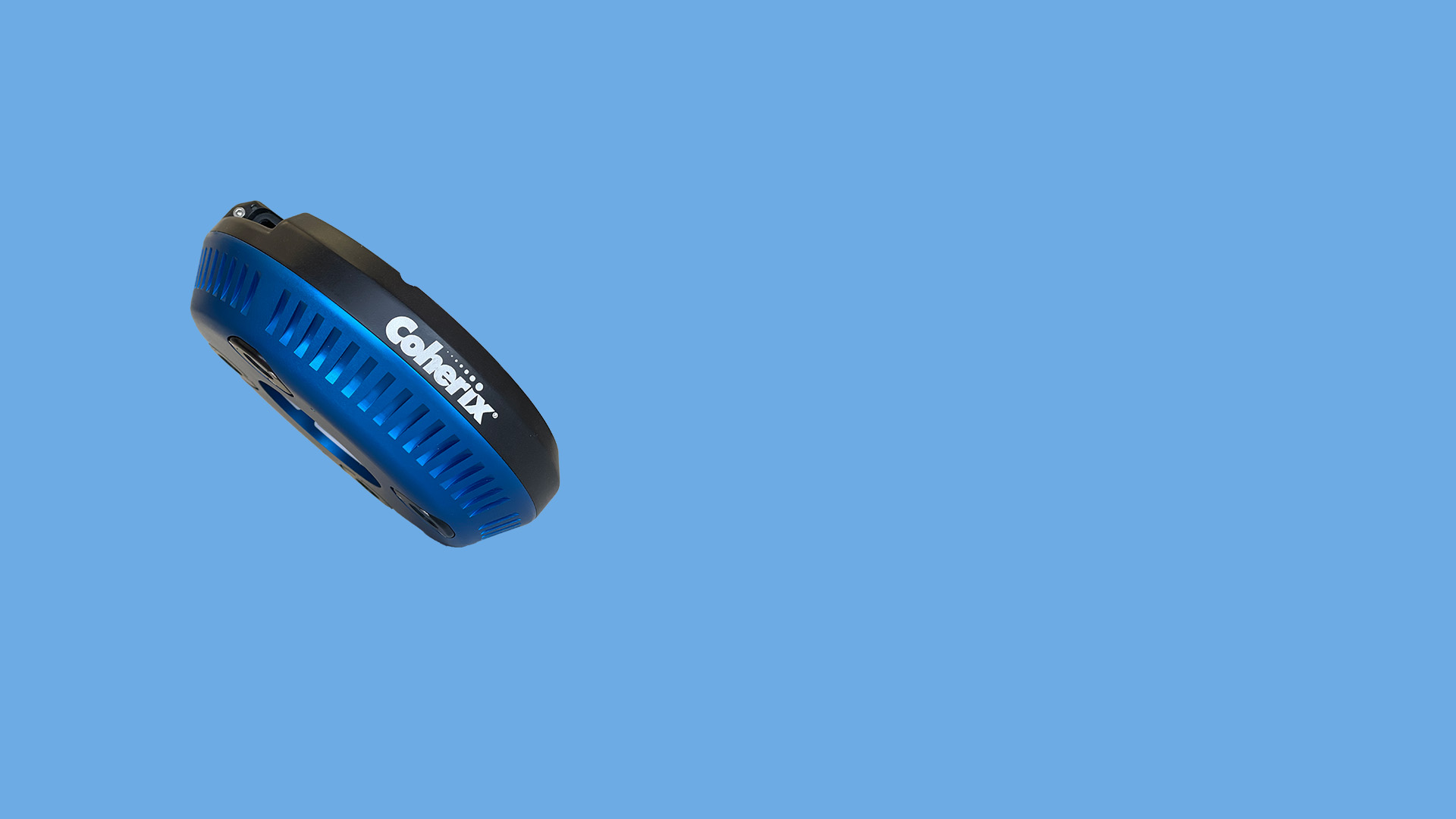

Coherix 3D SwirlMaster™ provides a complete in-line 3D inspection and process control solution for the adhesive swirl bead dispensing process. It improves bead quality, reduces process variation, and provides 100% part traceability. Coherix 3D SwirlMaster is a rugged, reliable, and on-the-fly inspection solution that ensures properly dispensed swirl beads without slowing down the manufacturing process.

Coherix 3D SwirlMaster is a specialized Coherix 3D sensor that analyzes adhesive swirl beads. With its 57mm field of view (FOV), the sensor can inspect swirl bead paths with no blind corners. It provides an industry-leading 3D machine vision solution with reporting on swirl bead height, width, volume, and location, and also identifies any gaps in a specified path.

The swirl bead pattern uses less adhesive to wet out a greater area than a traditional bead, while providing adhesion between two substrates. It also prevents squeeze out, making it aesthetically pleasing for parts that require it, such as closure panels in automotive manufacturing.

Coherix 3D SwirlMaster is not affected by part color or ambient lighting changes, providing robust operation even in “black-on-black” or “gray-on-gray” situations where 2D techniques fail.

Product Features

- Self-contained, around-the-nozzle solution

- Quick and easy setup

- Robot carried or pedestal mounted

- Robust 3D inspection of bead height, width, and volume 400 times per second

- Inspects bead in any direction without blind corners

- Accurate inspection of bead location relative to

part features - Configurable reporting and displays

- 100% part traceability with flexible archiving options

- Impervious to ambient lighting and part color changes

- Automatic adaptation to robot speed changes

- No added complexity in robot programming

- Rugged and crash-resistant, IP67 construction for sealed operation

- No moving components

- Large storage options (up to 1TB SSD)

- Easy maintenance

Once and done

Single-pass 3D swirl bead inspection is accomplished using four high-speed laser sensors leading and trailing the dispensing nozzle to track and inspect the adhesive when applied. Acquiring and processing 400 samples per second, Coherix 3D SwirlMaster has industry-leading acquisition speed, avoiding production slow-downs.

Easy to integrate

Coherix 3D SwirlMaster mounts around the dispensing nozzle. It easily communicates with whatever protocol your dispenser or robot uses and does not add complexity to robot programming. There are no time-consuming setup changes required for robot speed changes commonly required on other available systems.

Proven

Coherix 3D Inline Swirl Bead Inspection leverages a 3D high-speed imaging and processing platform, which has proven reliability, inspecting millions of customer parts to date. In addition, Coherix 3D technology has been widely deployed for bead inspection for numerous applications including powertrain RTV, body shop structural adhesive and sealants, final assembly urethane glass, battery thermal paste, and more with OEM and Tier suppliers globally.

Rugged

The Coherix 3D SwirlMaster sensor is built with a solid aluminum frame to withstand impacts and IP67 sealed housing that protects the unit in a production environment. There are no moving parts and Coherix 3D SwirlMaster is the online system that stays online.