Coherix Accelerates Implementations of their Tru3D Vision Assembly Verification/Error Proofing with Partner +Vantage Corporation

Ann Arbor, Michigan, July 24, 2014 — The robustness and stability of Coherix’s Tru3D vision technology and +Vantage’s industrial inspection and assembly equipment have partnered together to bring the most advanced technology solutions available to the manufacturing industry.

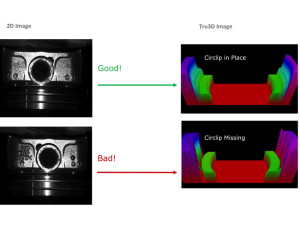

Solutions, such as ensuring a circlip is properly seated around a piston, are immediately available with this partnership. As a sensor and software company Coherix develops and brings to market 3D capabilities that are fast, accurate and hardened for the manufacturing industry allowing a partner like +Vantage to focus their expertise and resources on delivering inspection solutions for their customers, that are cost effective with state of the art design. These solutions lead to higher quality, increased throughput, reduced warranty and higher satisfaction for their customers.

Brad Pines General Manager of Coherix states “We are excited to have +Vantage as our strategic partner for Tru3D vision systems. The combination of low cost, state of the art 3D sensors from Coherix and +Vantage systems integration expertise will give unparalleled value to our customers. Our Piston Pin Circlip inspection systems are already completely eliminating warranty costs in current installations.”

Coherix designs and delivers high-speed, high-definition, 3D metrology and inspection tools for product development and the management of manufacturing processes for the precision manufacturing and semiconductor industries. Headquartered in Ann Arbor, Michigan the company has technical centers in Europe and the Asia Pacific region. Coherix products are being utilized around the world at companies such as ASE, SPIL, Marvell, BorgWarner, Ford, Honda, Allison Transmission, Chrysler, General Motors, Micron, Infineon, John Deere, Volvo Technology Transfer and Aisin among others.

+Vantage Corporation is a worldwide supplier of industrial inspection and assembly equipment. The primary area they serve is manufacturing and assembly, but their solutions are also utilized in proto-type development and product function testing. +Vantage has Divisions in USA, Mexico, and Asia.