Eliminate Design Redundancy with Structural Adhesive Process Control

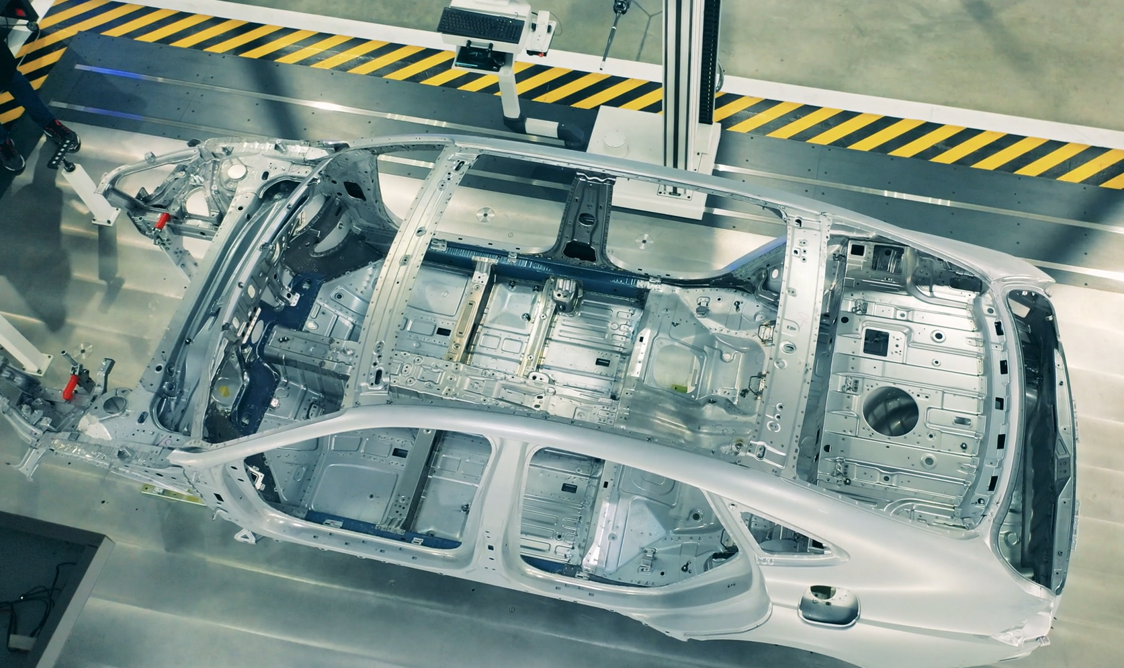

Investing in the adhesive dispensing process can significantly reduce Body in White (BIW) costs for automotive manufacturers.

Learn how the combination of real-time inspection and adaptive process control can fully guarantee quality and eliminate design redundancies in the SAE Paper “Invest in Adhesive Dispensing to Reduce Design, Capital, and Operational Costs” by Michael Lee, retired Ford Product Development Manager.

SAE Paper Abstract

Leveraging the increased use of Structural Adhesive in Automotive Body Structure Design has many proven benefits. It is a well-known method used to enable weight reduction in vehicle design and can also drive more efficient structural performance during dynamic safety events. This is increasingly important as vehicle safety standards increase, and as vehicle mass increases due to electrification. Often the benefits of adhesive use are not fully optimized due to unnecessary design redundancies or process driven redundancies. Design redundancy; using both welds and adhesive, is often included because government safety regulations require very robust validation of structures, and when combined with the use of Process Quality Control methods such as Batch Control and Sampling, can infer confidence in the design and process, but don’t ensure it. This paper proposes a different and unique approach to Product Design and Process Control, which will create an opportunity to eliminate redundancy, and can unlock significant design and process operational and capital cost savings. To truly ensure Quality Control of the structural adhesive bead, real-time verification along with Adaptive Process Control (APC) of the dispensing process is required. With fully guaranteed quality, design redundancies can be eliminated, and the design and processes can be concurrently optimized. The commitment to APC technology must happen very early in the Program, to enable an early focused design optimization effort to minimize the number of spot welds while maximizing structural adhesive use. Too often, the decision to invest in enabling technology in the manufacturing process, is made without considering design optimization. Also, the high-level decisions that can enable capital investment and operating cost savings are often caught in complex organizational finance processes. APC technology and equipment is purchased by Manufacturing entities, but without the confirmed product variable cost savings being identified early enough, the capital expenses won’t be justified or approved. This paper seeks to unravel that Catch-22 issue. Very few vehicle manufacturers are taking this pro-active step to commit to the use of APC technology in dispensing early in a vehicle program. Most OEM manufacturers design products in a very serial development process, design, tool, produce; with limited synergy due to the very rapid design cycle. They are missing a readily available opportunity to eliminate sub-optimization, added cost, added labor, and redundancy. To accomplish full efficiency and optimization, requires very close and early collaboration between the product design engineers and manufacturing engineers, and cross-organizational agreement.

Learn more about Adaptive Process Control for dispensing

Learn more about real-time inspection for structural adhesive