Transforming Manufacturing Quality Control with Coherix 3D Mini™

In modern manufacturing, speed and precision are essential. Yet many factories still rely on outdated 2D vision inspection systems, which can miss critical details and lead to costly errors. That’s why manufacturers are turning to advanced solutions like the Coherix 3D Mini — a cutting-edge 3D inspection system built for high-speed, high-accuracy performance on the production floor.

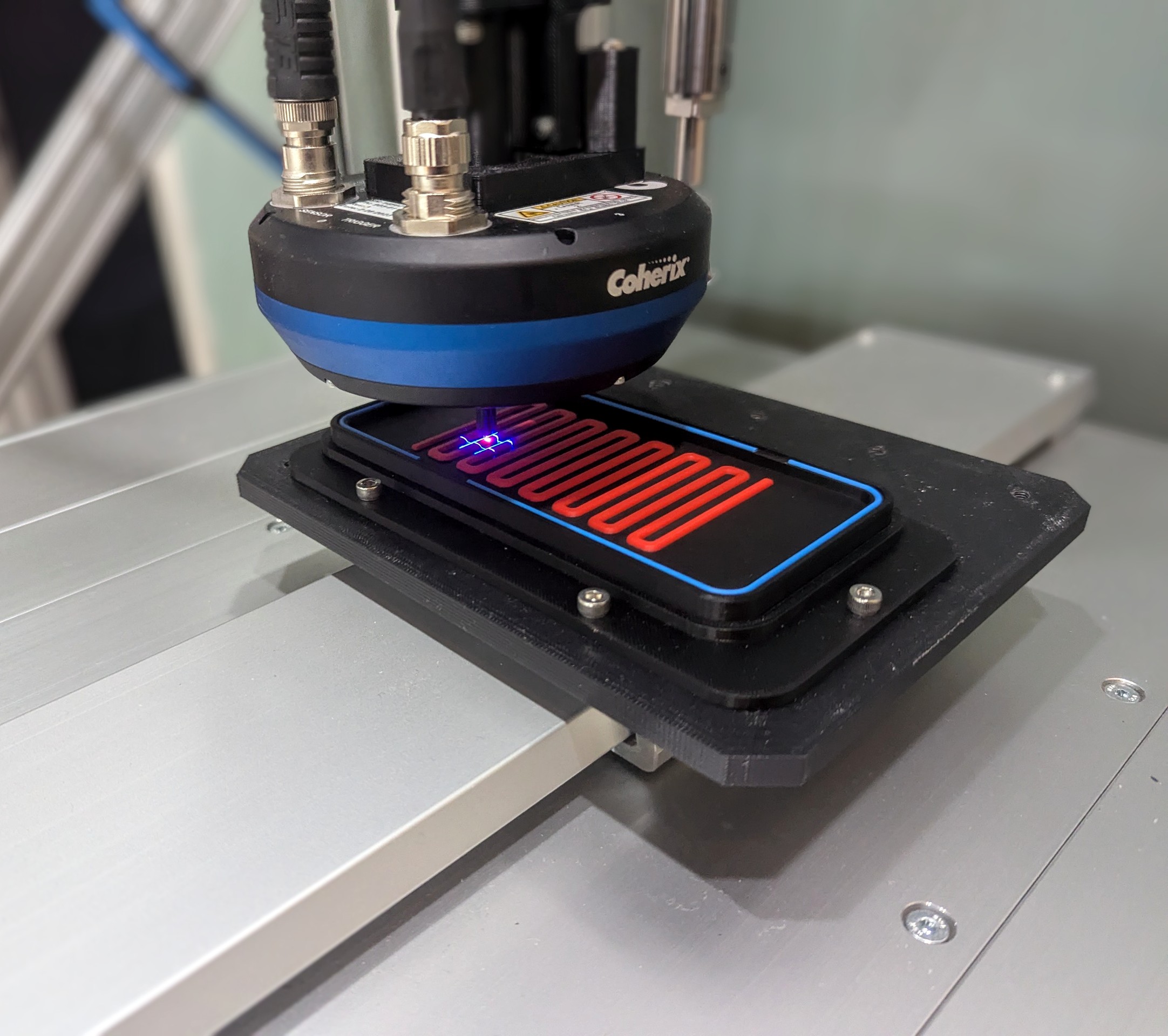

What Is Coherix 3D Mini?

Coherix 3D Mini is a compact, high-performance inspection system designed to outperform traditional 2D vision tools. It captures detailed real-time 3D data, enabling manufacturers to detect and correct process variations with a level of accuracy not possible using legacy systems.

Unlike 2D systems that rely on flat images, Coherix 3D Mini delivers true depth perception and surface topology, which is critical for inspecting complex parts and assemblies.

Boosting Accuracy with Adaptive Process Control

What makes Coherix 3D Mini truly unique is its integrated Adaptive Process Control (APC) solutions — intelligent software powered by artificial intelligence (AI) and machine learning.

APC constantly monitors production conditions, learns from past performance and adjusts in real-time to optimize dispensing accuracy. This self-correcting capability helps eliminate human error and ensures consistent quality — even when dealing with variation in materials, parts or environmental factors.

Benefits of Using a 3D Inspection System in Manufacturing

Implementing Coherix 3D Mini with Adaptive Process Control delivers measurable benefits for manufacturers:

- ✅ Reduce scrap rates: Catch defects early and make real-time corrections before bad parts pile up

- ✅ Minimize destructive testing: Trust in accurate, non-contact inspections to reduce reliance on teardown testing

- ✅ Lower labor costs: Automate inspection tasks and free up skilled labor for higher-value activities

These improvements not only boost operational efficiency but also help meet quality standards and reduce overall production costs.

Why Manufacturers Are Moving Beyond 2D Inspection Systems

The limitations of 2D inspection systems — including inconsistent accuracy, limited surface detection and a lack of adaptability — are becoming more apparent in today’s complex manufacturing environments. As a result, more companies are transitioning to 3D inspection technology powered by AI-driven process control to gain a competitive edge.

Future-Proof Your Production Line

Whether you’re in automotive, electronics or industrial manufacturing, the Coherix 3D Mini offers the intelligence, precision and reliability your operation needs to stay competitive.

🔍Learn more about how Coherix 3D Mini is revolutionizing manufacturing quality control

🔍Check out how Adaptive Process Control solutions improve quality and throughput