Coherix Tru3D Assembly Verification/Error Proofing Technology Eliminates Piston Pin Circlip Errors at Large Automotive OEM

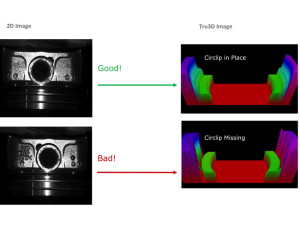

Ann Arbor, Michigan, November 6, 2014 — Coherix Tru3D™ Assembly Verification/Error Proofing Technology eliminates piston pin circlip assembly errors at a large automotive OEM by verifying correct installation and placement of circlips in the piston to properly contain the piston pin. The Tru3D™ technology inspects both sides of each piston for conditions, such as; missing clip, double clip, incorrectly seated clip and clip orientation. Faulty installations of piston pin circlips can cause a sudden engine failure. The result can be very costly OEM warranty issues.

Existing piston pin assembly line inspection stations have been retrofitted with the Tru3D™ technology. As designated by the OEM’s Bill of Process Tru3D™ will be incorporated into new assembly lines. The flexibility of Tru3D™ provides assembly verification/error proofing in a manual or automated assembly line.

Coherix designs and delivers high-speed, high-definition, 3D metrology and inspection tools for product development and the management of manufacturing processes for the precision manufacturing and semiconductor industries. Headquartered in Ann Arbor, Michigan the company has technical centers in Europe and the Asia Pacific region. Coherix products are being utilized around the world at companies such as ASE, SPIL, Marvell, BorgWarner, Ford, Honda, Allison Transmission, Chrysler, General Motors, Micron, Infineon, John Deere, Volvo Technology Transfer and Aisin among others.