Coherix 3D Mini Featured in Manufacturing Quality

This article originally appears on the Manufacturing Quality website.

Coherix reduces manufacturing costs in the automotive, medical, and electronics sectors

30 September 2024

“This is the first laser-based 3D adaptive-process-control system of its kind available for use by the automotive, medical and electronics industries.”

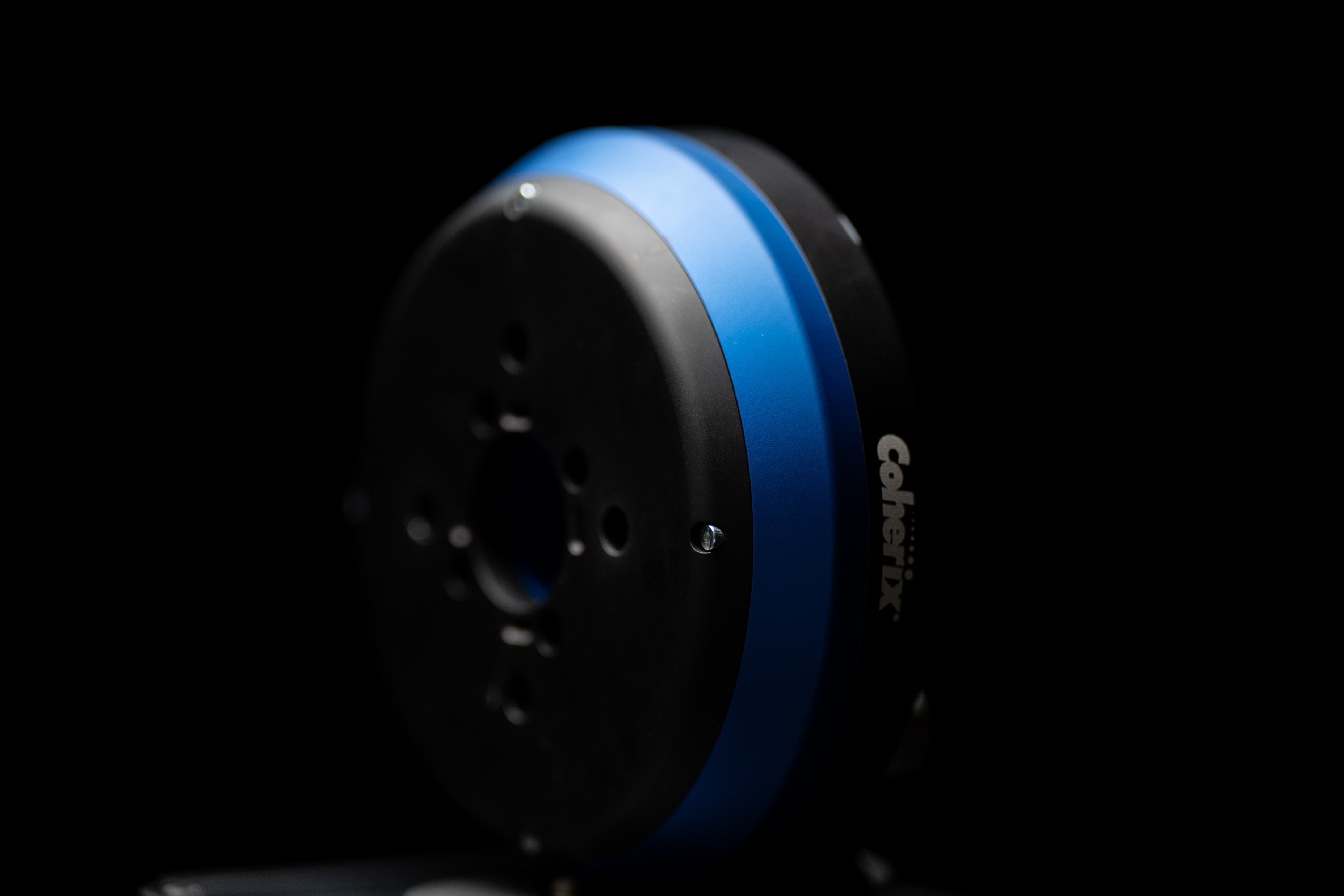

Coherix has revealed its “industry-first” technology that works to monitor and adjust the application of adhesives and sealants used to manufacture automotive, medical, and consumer electrical products. The Coherix 3D Mini can track adhesive beads in small, critical assemblies for products including cell phones, computers, medical devices, and automotive electronic-control modules.

Once combined with the Coherix adaptive process-control software, the system can monitor and adjust the application of adhesives, so each part meets the required specification.

According to its developers, the new 3D laser-based computer vision system aims to reduce manufacturing costs without compromising on quality. Coherix President, Juergen Dennig, believes the new solution will reduce assembly-line operating costs by up to 20%. He goes on to point out that a beta test with a major electronic control manufacturer saw an estimated annual saving of up to $160,000 in operating costs after installing eight 3D Coherix sensors on one assembly line.

“Coherix 3D Mini with adaptive process control eliminates the need for additional inspection stations,” said Dennig. “There also will be a significant increase in production volume along with considerable labour, and material, cost savings.”

Key features of the Coherix 3D Mini:

- Reduces manufacturing costs without compromising on quality assurance.

- Operates at a speed of 400 times per second.

- Ideal for use in the automotive, medical, and electronics industries.

- Requires users to obtain less than two days of training before being able to utilise the system.

- Coherix provides remote training, assistance and advice.

“This is the first laser-based 3D adaptive-process-control system of its kind available for use by the automotive, medical and electronics industries. It could be years before a truly competitive product emerges,” continued Dennig.

Looking into potential markets where the Coherix 3D Mini could make waves, Dennig points to China being “the biggest potential market,” followed by Europe and North America.

“China’s rapidly expanding production of electric vehicles and other electronic products makes it the single largest potential market for this new technology,” he concluded. “Europe also is an attractive market because of the large number of dispensing and robotics companies located there. In North America, Mexico is emerging as an attractive market as well.”