Adaptive Cost Control – Article from SME Advanced Manufacturing

Adaptive Cost Control

Artificial Intelligence, machine learning and 3D-vision systems work with process-control software to improve manufacturing quality in a variety of industries

Dwight Carlson, Chariman and CEO, Coherix

August 28, 2024

Adaptive process-control technology has the potential to save automotive and consumer-electronics manufacturers millions of dollars in assembly costs.

Paired with an automated adhesive-dispensing system equipped with 3D-inspection technology, adaptive process control (APC) can dramatically reduce the number of spot welds and rivets automakers use to assemble vehicle body structures, also known as bodies in white.

Electric vehicle (EV) battery quality has become increasingly important as more and more electric and hybrid-electric vehicles take to the road. Adhesive dispensing systems teamed with APC for the assembly of lithium-ion batteries also can significantly improve quality and cut costs.

In addition, the use of adhesives is expected to increase as car manufacturers transition to electrification and switch to lighter weight materials such as aluminum and composites to reduce vehicle weight and boost fuel economy and driving range.

A 25% reduction in welds for the annual assembly of 100,000 vehicles could deliver variable-design cost savings of as much as $30 per vehicle and save $2.5 million more by reducing the need for welding equipment, according to Michael Lee of MJ Lee Technical Insight LLC. Lee writes in the SAE technical paper “Invest in Adhesive Dispensing to Reduce Design, Capital and Operation Costs” (2023-01-0605) that a 25% cut in welds over five years could save $17 million along with a $20 million savings in design and capital equipment expenses.

A commitment to APC needs to take place early in an automaker’s product development process to minimize the number of rivets and welds. Early design optimization and product design collaboration with manufacturing engineering along with an additional focus on structural adhesives and APC are all keys to unlocking design, capital and operating cost savings.

Adaptive process control linked with machine-learning, artificial intelligence (AI) and 3D-vision technologies also can improve EV battery safety, service life and quality while reducing production costs. Manufacturers worldwide are in a race to improve battery quality, safety and performance while reducing weight and cost. The mass production of EV batteries is still in its infancy and many companies are developing quality-control processes on a trial-and-error basis.

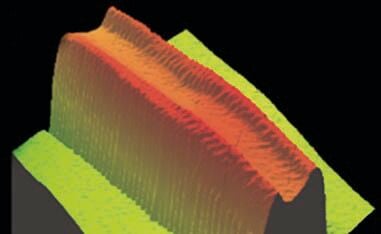

The application of adhesive sealant to properly close battery covers and packs is a major challenge. Although most companies today rely on 2D-inspection systems to check quality, laser-based 3D-vision systems are significantly better. Two-dimensional systems are affected by ambient light, unable to detect adhesive volume and cannot monitor critically important sealant-application data such as bead shape, center height or cross-section measurements.

The application of adhesive sealant to properly close battery covers and packs is a major challenge. Although most companies today rely on 2D-inspection systems to check quality, laser-based 3D-vision systems are significantly better. Two-dimensional systems are affected by ambient light, unable to detect adhesive volume and cannot monitor critically important sealant-application data such as bead shape, center height or cross-section measurements.

On the other hand, a 3D system when linked to APC software automatically can check and adapt the application of adhesives at line speed for batteries and battery covers to improve quality, cut downtime and reduce labor and material costs. Adhesives alone can cost $90 or more per gallon. APC and 3D-vision technologies have been proven to reduce the amount of sealant used in the assembly of battery packs and covers by up to 30%.