Nordson-Coherix Fully Integrated Bead Dispensing, Inspection, and Process Control Solution

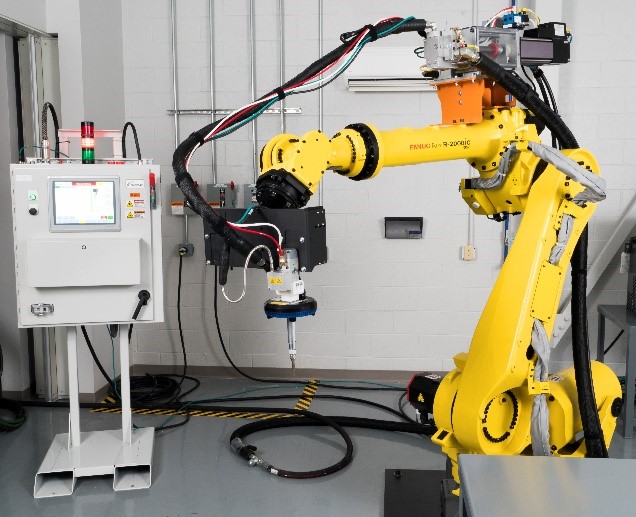

Ann Arbor, Michigan, December 17, 2018 — Coherix, Inc., a global leader in Three-Dimensional (3D) Machine Vision, proudly announces its Predator3D™ bead inspection solution has been fully integrated into the Nordson® Process Sentry™ PLC dispensing controller with Pro-Meter® S PLC, ideal for automotive OEM and tier-one body structures and glass assembly. Nordson Automotive Systems Group is one of the global leaders in precision dispensing and related technologies for adhesives, industrial coatings, sealants, paints, polymers, and fluids

With Coherix Predator3D integrated, Nordson Proess Sentry PLCdispensing controller gains the ability to inspect, report, and auto correct, while dispensing and providing instant feedback for optimum process control. Predator3D is not affected by changes of ambient lighting or part color, and therefore it can perform robust 3D vision operations even in black-on-black or gray-on-gray situations.

Comparing to traditional bead inspection technologies (such as Confirmation Laser and 2D Vision system), Process Sentry PLC 3D Vision with Predator3D embedded has absolute superior advantages (as shown in the table below).

About Coherix, Inc.

Coherix, Inc. develops and manufactures high-speed, high-definition 3D machine vision solutions that enable our customers to manage high-volume precision manufacturing processes. Coherix solutions are designed for inspection and error-proofing in the automotive, semiconductor, and electronics industries. Coherix is committed to producing the highest performing 3D machine vision products at the lowest Total Cost of Ownership. Coherix customers and partners include global end users, system integrators, and distributors, who demand 100 percent reliability that Coherix products provide. Headquartered in Ann Arbor, Michigan, the company has offices in the United States, China, Germany, Singapore, and Japan.