Coherix Continues to Advance the Art of Holography by Offering Thickness Measurement with ShaPix

Ann Arbor, Michigan, October 30, 2012 — Coherix®, a leader in advanced Robust3D Measurement and Inspection solutions for manufacturing, has released new Thickness Uniformity capability in its latest version of ShaPix® Analyzer Software. This breakthrough in opposing surface (top & bottom) analysis results in the ability for ShaPix® users to evaluate, in full 3D, the relationship of two surfaces for co-planarity and thickness uniformity of the parts. This functionality is especially useful for parts such as valve bodies or brake rotors.

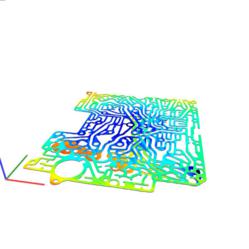

ShaPix’s non-contact 3D imaging and analysis software allows manufacturers to view full 2D & 3D topographical color visualization maps of the entire planar surface area, at the micron level. While our analysis software has always provided multi-surface relationship (Height / Linear / Profile, Co-Planarity), it has been limited to a single side of a part,” said Michael Mater, Chief Engineer for ShaPix. “There are many parts such as brake rotors that have multiple machined surfaces on both sides. The precise relationship of these surfaces is critical to the disk rotor function and performance. The ability to measure each side and stitch the measurements into the same coordinate system enables process operators and engineers to clearly visualize the parrallelism between the surfaces in full 3D. We believe this will be a major advantage for customers when they are setting up and controlling their manufacturing processes.”

Thickness Uniformity capability is included in ShaPix® systems starting in Q4 of 2012. Customers with existing ShaPix® systems can contact Coherix® for information on upgrading their ShaPix Analyzer Software to include this breakthrough capability.

About Coherix®

Coherix® is a privately held, global supplier of high-speed, high-definition 3D visualization and inspection solutions designed to improve the management of manufacturing processes. Headquartered in Ann Arbor, the company has technical centers in Europe and the Asia Pacific region. Coherix® products are being utilized around the world at companies such as Intel, Amkor, BorgWarner, Ford, Honda, MAG, Chrysler, General Motors, Micron, Infineon, John Deere, Volvo Technology Transfer and TRW among others.